Ezcad3 Software+DLC Series Control Card

Ezcad3Laser Marking System | |

Software | EZCAD3 |

Hardware | DLC Controller |

Surface | USB/PCIE/ETH |

REMARK | ✔ |

Camera Display | ✔ |

Fly Marking | ✔ |

Multi Galvo | ✔ |

Software Development Kit | ✔ |

2-Axis Control | ✔ |

Offline Marking | ✔ |

2.5D | ✔ |

3D | ✔ |

Integration of Extended Axes and the Galvo | ✔ |

Uniform Marking | ✔ |

4-Aix Motion | ✔ |

TCP/IP Remote Control | ✔ |

Speedy Bar Code | ✔ |

Galvo Protocol | XY2-100, XY2-100(beefed-up version), SL2-100, |

High-precise Calibration of Galvo | 257*257 |

Feedback of Galvo Position | ✔ |

Display of Galvo Status | ✔ |

Linear Change of Scanner Power | ✔ |

Lasers | Mainstream Lasers Supported |

Linear Change of Laser Power | ✔ |

Display of Laser Status | ✔ |

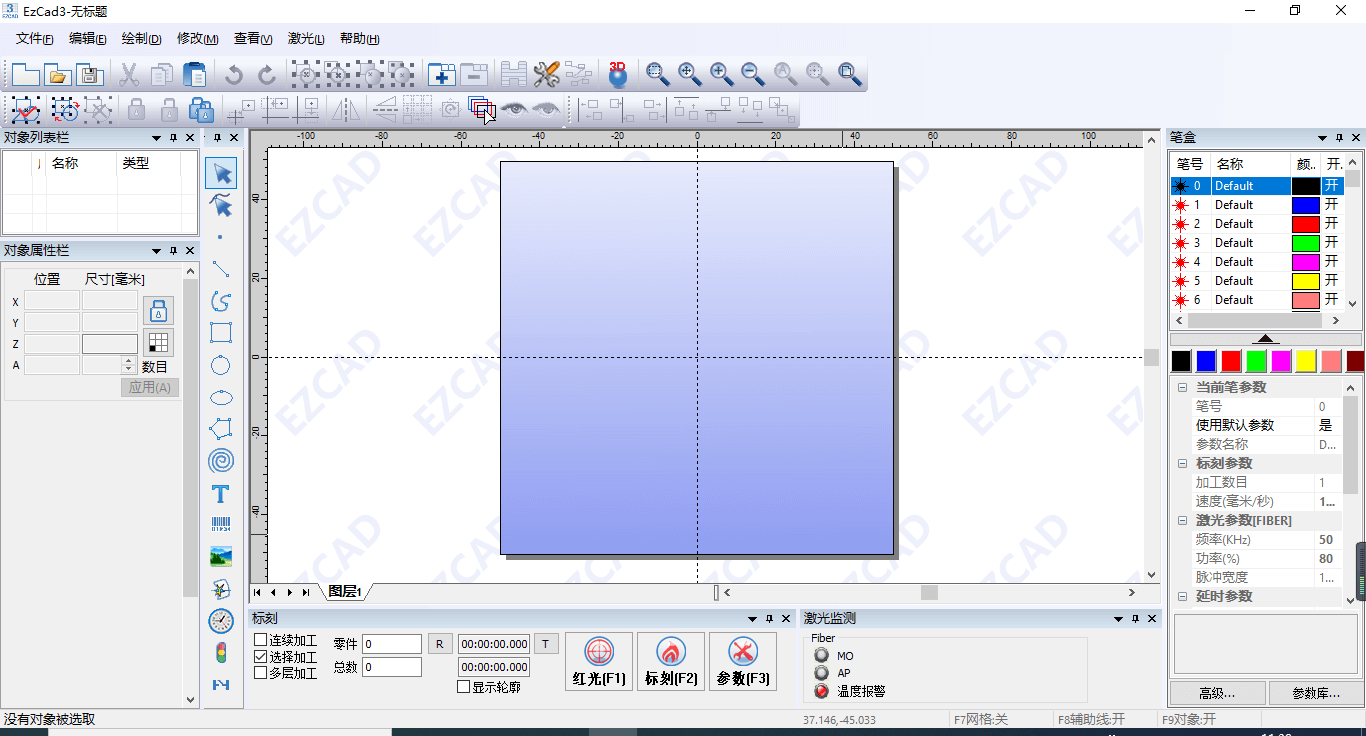

Software

Main Configurations | |

Software Kernel | 64 Bits |

Lasers | The 1.0 digital communication protocol is compatible with almost all lasers on the market, such as CO2, YAG, FIBER, and SPI. The current, pulse frequency, duty cycle, and other parameters can be adjusted by the software according to the parameters of different lasers. In addition, the laser status can be displayed in real time. |

Red Light Pointer | Red light works as an indicator. |

Password | Aversion of deliberate modification of parameters. |

IO Control | New. Automation possible. |

Galvo Calibration | 3D calibration, traditional trapezoid calibration, barrel (pillow) calibration, and parallelogram calibration. Special calibration software for extremely accurate calibration results. |

Hatch | Background hatch,ring-like hatch, angle hatch, cross hatch. Distance and contour adjustable. |

Processing Functions | Large-format dynamic focus, projector positioning function, multiple extension axes, estimated processing time, speedy spot-marking of 2D bar code, average distribution of line, power and velocity linear change, helix and sine curve wobble, and material parameter assistant |

Edit Functions | multi-layer, 3D curve marking, slicing function, dynamic hatch, 3D curve projection, curved surface wrapping, bitmap file 2.5D engraving, random curve text, random drawing/editing, uncombined/combined, group/ungroup, cancel/restore, welding, trimming, cross hatch, align, curve auto-connection, etc. |

Text Functions | Support of TrueType fonts, single line fonts (JSF), dot matrix fonts (DMF), SHX, and user-set fonts |

Support of Max 256 Layers Processing | Customizable. Easy to set different processing parameters |

Bar Code and 2D Bar Code | Code39, EAN, PDF417, DATAMATRIX, QR, etc. |

3D Model File | STL, DXF |

Vector File | PLT, DXF, AI, DST, SVG, GBR, NC, JPC, BOT |

Bitmap File | BMP, JPG, JPEG, GIF, TGA, PNG, TIF, TIFF |

Variable Texts | fixed text, date, time, keyboard, jump number, file, dynamic file, EXCEL table, TXT file, serial communication, and network communication |

Language Package | Various languages available, such as Chinese and English. |

Optional Functions | Dual-axis marking, fly marking, Software Development Kit |

Calibration | Support of loading and switching of max 4 calibration files online |

Multi XY layer calibration | Significant increase of XY layer precision |

Offline Layer | Support of switching and processing of 16 offline layers |

Online Arc Interpolation Command | Suitable for the processing of high precision small circle |

Contact Us

Service Hotline

Suzhou JCZ Technology Co., Ltd.

Address: m3-103-2, microsystem Park, Suzhou science and Technology City, No. 2, Peiyuan Road, Huqiu District, Suzhou, Jiangsu

Guangdong JCZ Technology Co., Ltd.

Address: room 1002, No. 4, Songhu Zhigu R & D center, No. 1, renju Road, Liaobu Town, Dongguan City, Guangdong Province

Beijing JCZ Technology Co., Ltd. Wuhan Branch

Address: 1101, block B, building 1, modern service industry base, Huagong science and Technology Park, University Park Road, Jiangxia District, Wuhan, Hubei Province

Copyright © 2022 Beijing JCZ Technology Co., Ltd. 京ICP証000000號