Zeus Laser Marking System

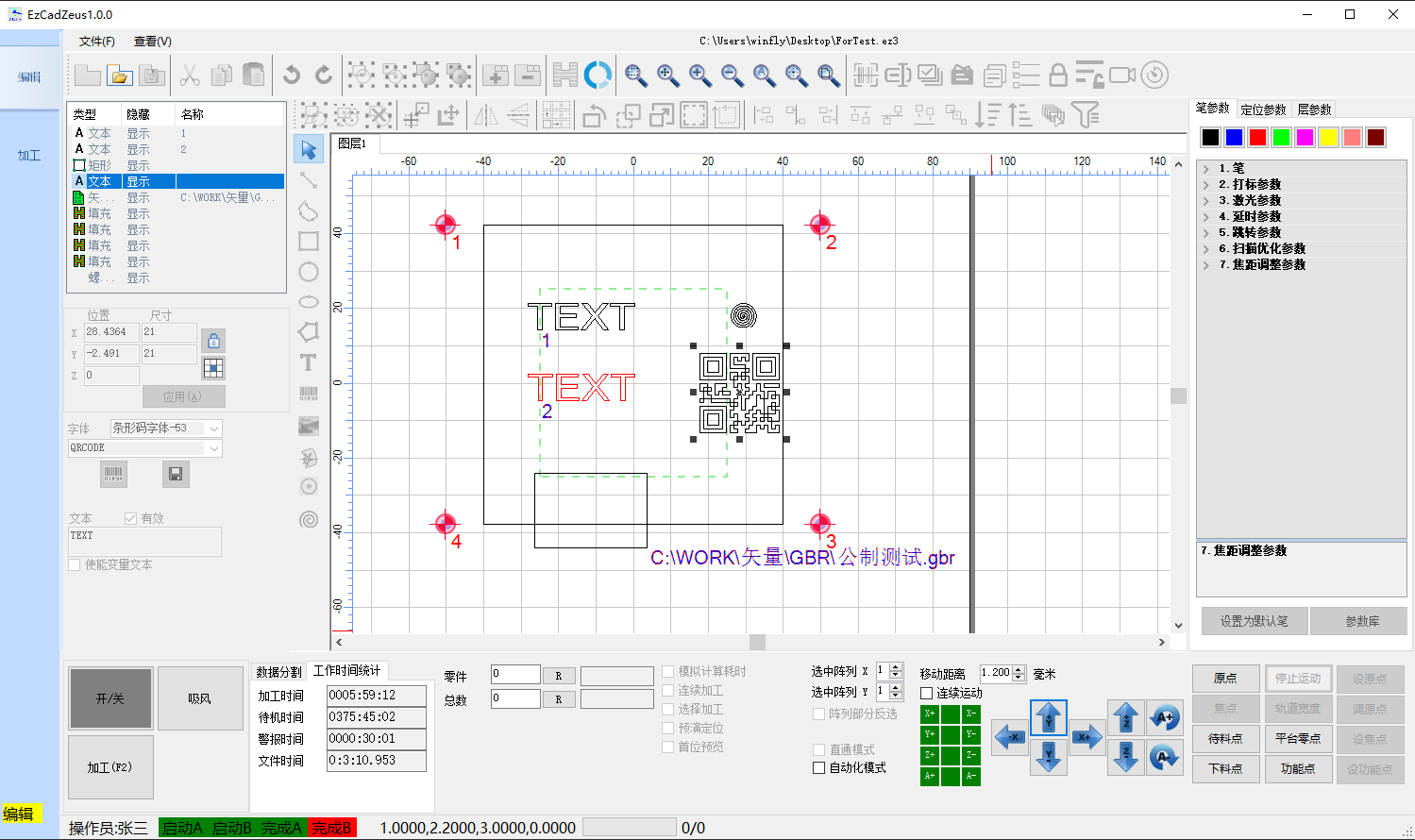

Software Interface

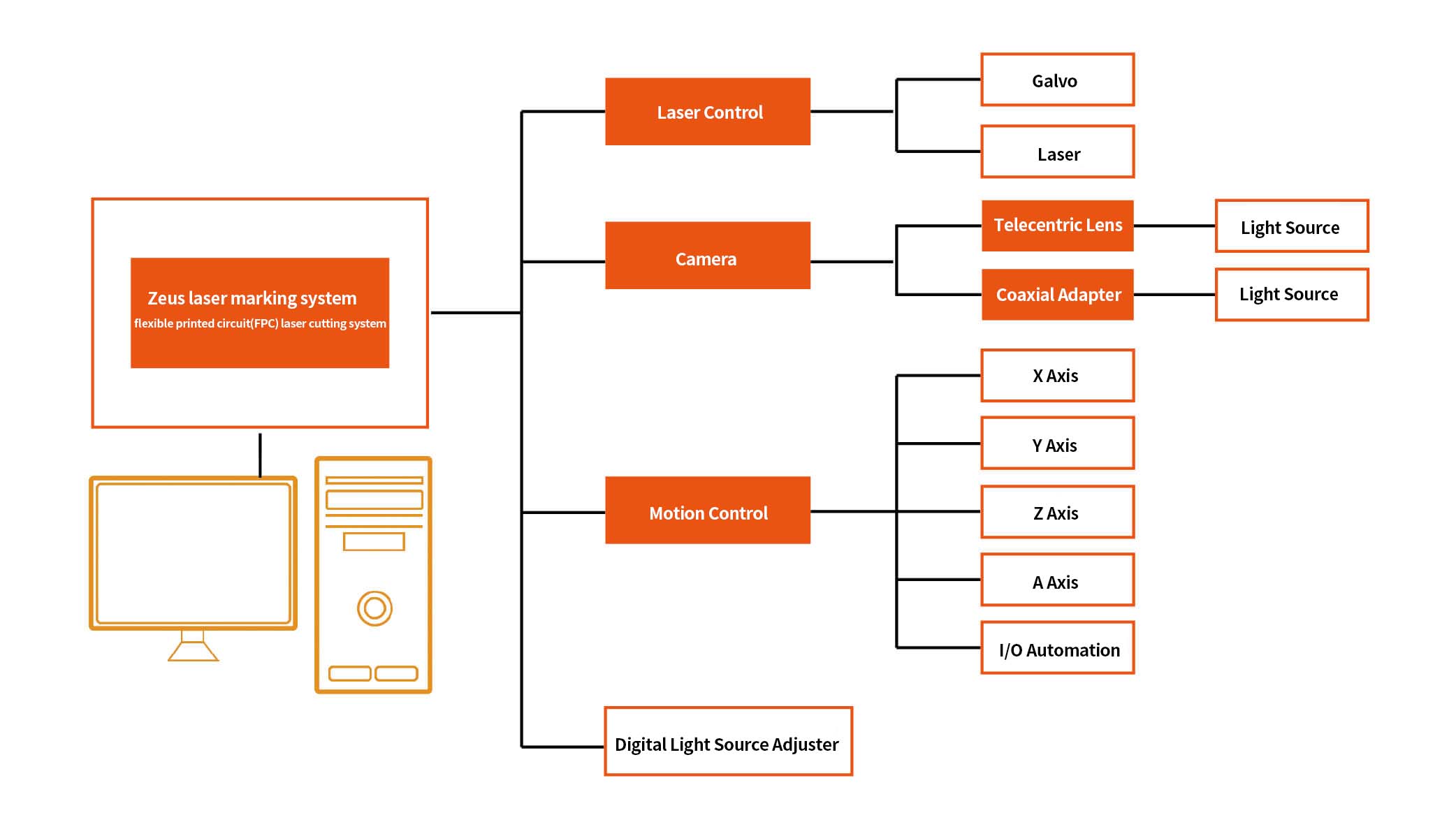

System Structure

Advantages

Accuracy

Secondary offset for positioning point, light path offset, automatic detection of kerf cutting effect, automatic identification and verification of processed barcode, focal length offset for designated areas, motor control by bus mode, multiple scanner protocols, custom area/order offset

Efficiency

Large field for multi-product positioning, inlet and outlet supply, roll cutting, multiple stations, multiple lasers, optimization of processing path

Convenience

Open MES communication, EMAPING, closed-loop factory management, built-in CAD function for optimal editing of drawing files, compatible with multiple brands of laser communication and control, various scanning solutions, custom procedures for automation needs

System Performance

Multi-axis Motion

Combined with the simultaneous operation of the scanner and the XY station, its processing results are extremely better than that of scanner processing. Compared with the traditional splicing processing, the integrity of cutting lines is guaranteed besides the efficiency of the scanner processing.

Fly Positioning Marking

During the acquisition of MARK points, the camera and the workpiece remain in relative motion, which improves productivity by reducing the time from motion deceleration to standstill compared with the cycle mode of motion-stabilization-image acquisition.

Applications

Laser Cutting of Flexible Printed Circuit(FPC) Board

FPC features small in size, thin thickness, lightweight, and short cycle for design and production. In the final cutting procedure of FPC production, the accuracy and stability of the cutting position are extremely important. Otherwise, a large number of FPC will be wasted. Traditional die-cutting requires die-casting according to the product, whose production cycle is long. In contrast, Zeus laser marking system(or laser cutting system of flexible printed circuit board) only needs product drawings and simple editing to complete the setup of dies. With the miniaturization of electronic products, the need for FPC cutting equipment is increasing.

Laser ITO/ Silver Paste Etching

ITO film, a typical transparent conductive material, is widely used in touch display devices, solar energy, outdoor glass, and other fields. Etching circuit structure on its surface is needed in its production. The traditional chemical method is unable to process high-density products in small sizes. By comparison, Zeus laser marking system(or laser cutting system of flexible printed circuit board) is advantageous to laser etching due to its effective control of the spot size and its adjustment according to die sizes through software, therefore increasing yield. In addition, only import of drawings to edit products is needed, which is simple, convenient, and low cost.

XYZA Four-axis + Galvo Processing

Zeus laser marking system(or laser cutting system of flexible printed circuit board) can accomplish multi-sided processing or marking by coordinating XYZA axes, fixtures, and 2D Galvo. Simple and self-set editing is available with the guarantee of accuracy and efficiency. It is also suitable for product processing in small quantities and no special dies are needed for different equipment.

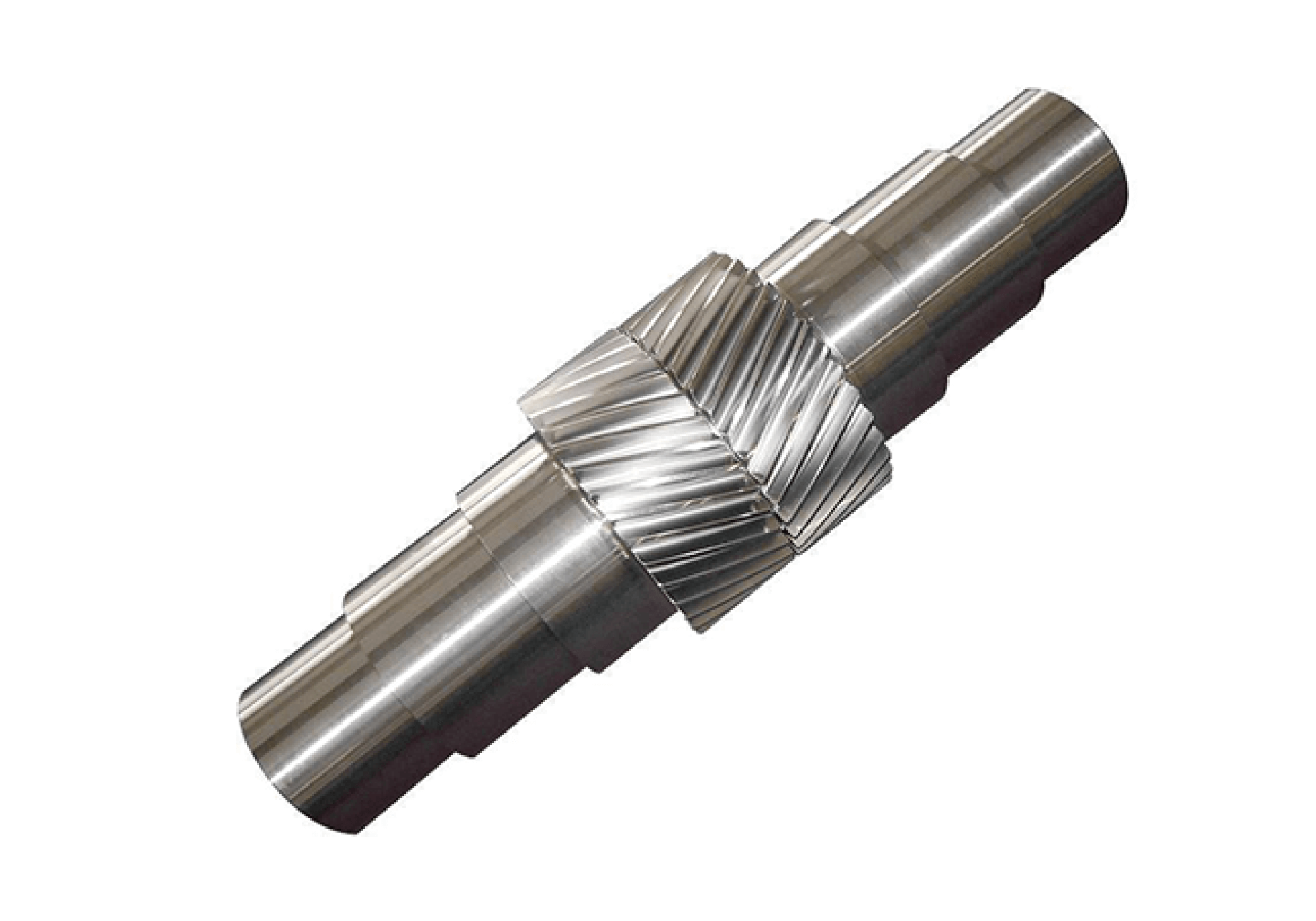

Surface Splicing of the Multi-diameter Long Axis

The inaccurate distortion calibration of the 2D scanning area results in an obvious splicing line in columnar splicing of the circular axis. The processing difficulty increases for circular axes with multiple diameters. Zeus laser marking system(or laser cutting system of flexible printed circuit board) edits drawing files with different diameters separately by layers, which is convenient and simple.

Microporous Processing

Micro-hole drilling is common in metal processing. High yield can be actualized through laser micro-hole processing due to its non-contact processing without mechanical force. Combining the short-pulse light source, hard and brittle materials, such as ceramics and glass, can be processed. The adjustment of Z-axis parameters to solve 2D scanner’s taper inconsistency to achieve effective control of workpieces’ height and maintain effective focal length processing. The processing area can be expanded by the use of XY axes and the accurate processing area can be positioned by the use of JCZ visual positioning system.

Contact Us

Service Hotline

Suzhou JCZ Technology Co., Ltd.

Address: m3-103-2, microsystem Park, Suzhou science and Technology City, No. 2, Peiyuan Road, Huqiu District, Suzhou, Jiangsu

Guangdong JCZ Technology Co., Ltd.

Address: room 1002, No. 4, Songhu Zhigu R & D center, No. 1, renju Road, Liaobu Town, Dongguan City, Guangdong Province

Beijing JCZ Technology Co., Ltd. Wuhan Branch

Address: 1101, block B, building 1, modern service industry base, Huagong science and Technology Park, University Park Road, Jiangxia District, Wuhan, Hubei Province

Copyright © 2022 Beijing JCZ Technology Co., Ltd. 京ICP証000000號